Your eyes are windows of your soul, but many people consider them for seeing. But it is difficult to argue how much eyesight protection is essential for you. People claim that their regular eyewear is safe then why standard ANSI Z87.1 is vital for eye protection.

The Z87.1 is the basic standard that shows which requirement you need for safety glasses. Besides, Raksha Bandhan, they must meet the safety standard test.

The ANSI standard meets the range of certain things as the minimum thickness of lenses and marking + sign on all safety goggles. For goggles, they must have impact resistance because all safety eyewear passes through impact tests.

Testing:

ANSI Z87.1 standard proved through four different qualifying

tests.

·

Test 1:

This is one of the lowest test forms that is done by a steel ball of 1 inch that is falling from 50 inches. The steel ball is like a golf ball that hit in the eye and thrown from a few feet distance. If eyeglasses pass this first test, it means they meet the Z87.1 standard.

Now they are good protective but cannot include in safety gear. Before buy safety glasses, you need to wait for the passing of other tests. Because this test is not enough for eyewear qualifying, and they are hazards on power.

For working in the hazards area, your protective eyewear should have stamped with marking of Z87+ because this marking symbol shows that these eyeglasses are submissive, but they have to pass the other two tests.

·

Test 2:

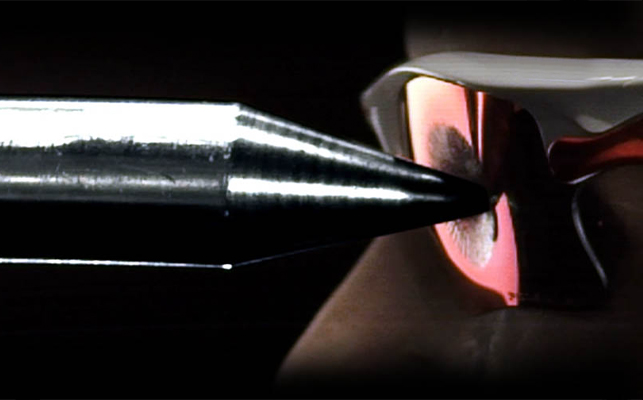

In this test, a steel ball with 0.25-inch width is fired

from different six certain spots over lenses at the speed of 150 feet per

second. This is the same hitting to shot eye with BB gun. So, if your safety

eyewear passes this test, they are ready to wear in hazards places. But still,

wait for the next test.

·

Test 3:

The round of this test is high impact and performed by steel

missile of 17.6-ounce and weighing one pound, and then they are dropped from

50-inches. You can compare this test with the head of a hammer or shovel that

can hit in the eyes.

·

Test 4:

This is a final test, and performed by the dropping of a

sharp needle which has weight is 1.56 ounce that hit on the 50 inches lens.

This test can compare with a dart that can hit into the eyes.

·

Conclusion:

Throughout these tests, if no part of eyeglasses breaks and even no fragments should disconnect from the frame, it is qualifying to add in the Z87+ badge.

Origin of ANSI standard:

The first standard for eyes and face protection began in 1922, and the first edition was Z2 standard for the National Bureau of Standard of war and Navy Department. Z87 design was approved in 1968 for eye and face protection and then Z87.1 in 1968 as well.

Since that day, Police

Safety Sunglasses, the Z87.1 standard has revised at least five times

that were 1979, 1989, 2003, 2010, and 2015. All these revised editions remained

the same with minimum changing for face and eye safety.

Key Changing of ANSI Z87.1:

The 2003 and predecessor products made by certain types of devices. Every device has a standard chapter that shows the device, optical characteristics, and required testing that make them the standard for PPE.

The 2010 edition was for hazards and, therefore, it's making based on the hazard’s nature. These hazards were droplets or splashes, fine dust, and optical radiations. That was a dramatic shifting of standard from product configuration to hazard base structure.

Due to this shifting, this encourages to choose an appropriate selection for the hazard’s safety. But the user has to match the threat for which they require a safety device. The 2015 revise edition focused on creation performance, and coordination should have a global standard.

Besides, they revised the 2015 edition from the little

changes in the 2010 edition. Both revised edition of 2010 and 2015 report

aftermarket mechanics. All original and non-original equipment manufacturing

was not the same, and they did not sell with the original device. Moreover, the

side shields were tested on the typical frame for which that product made.

Marking of ANSI Z87.1:

The 2003 edition had a two-level base test that was basic and high-impact. The lenses should have marked with the basic impact, and there should be no additional mark, but high-impact lenses need Z87+ marked.

If

possible, Constriction

Safety Tips, the lenses should mark with appropriate tint for a

different purpose. All safety glasses at least one temple, goggles frame, and

removable side shields should mark with the monogram of Z87 and Z87+.

0 Comments